ENGINE

521

2016 OFFROAD CATALOG

accessories

body

handlebar

& grips

cables &

levers

engine

fuel &

intake

electrical

& ignition

clutch

drive

bearings

brakes

steering &

suspension

tires

tools &

shop

exhaust

FORGED BOTTOM END ADVANTAGE

The foundation of any bottom end rebuild is a solid forged

crankshaft assembly, which provides strength and reliability far

surpassing any cast part that lacks consistency. Forged crank-

shafts due to their lighter weight, more compact dimensions and

better inherent dampening, rev higher and run smoother than

their cast counterparts.

This part of the engine has a huge amount of stress due to twisting

and bending 1000's of times a minute while running under load,

you don’t want an inferior product here to ruin a motor. Wiseco

engineers have designed our crankshafts to meet or often exceed

OEM tolerances giving you the best base for your bottom end.

CRANKSHAFTS / CONNECTING RODS

Wiseco powersports crankshafts feature a double forged connecting rod made from dedicated forgings. The rods maintain supe-

rior strength, durability, and dimensional consistency through improved grain flow. Shot peening eliminates residual stress and

oil slots are located to maximize lower rod oiling and extend bearing life.

Coated bronze thrust washers have a dimpled design to increase oil retention and reduces stress between the connecting rod,

washer, and crank web. Double-drilled small ends provide the piston pin with extra lubrication and cooling, reducing distortion

of top end due to thermal transfer from the piston.

Wiseco has designed these crankshafts and connecting rods to work together with our pistons to provide the smoothest rotating

assembly possible. Having a complete bottom end that is made of 100% forged material will give you the piece of mind that your

motor will be able to withstand any abuse within reason.

Professional racers as well as weekend riders choose these solid kits to reduce failure rates and take advantage of the horse-

power and immediate torque a light weight bottom end can deliver.

BOTTOM END KIT FEATURES

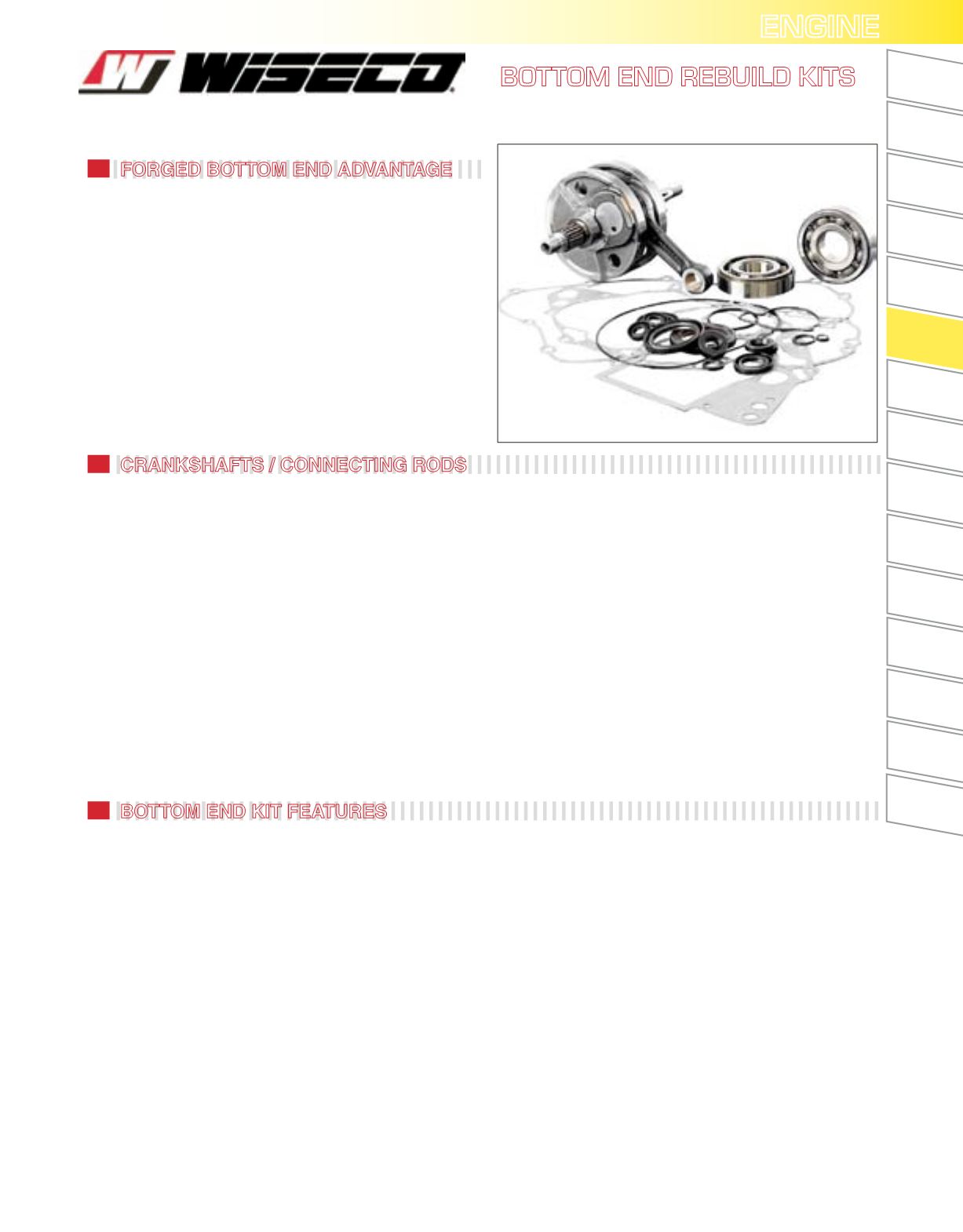

• Each kit contains everything you need to complete your rebuild the right way, the first time- crankshaft and connecting rod, all

applicable bearings, and complete bottom end gasket kit made to meet or exceed OEM.

• Wiseco connecting rods are double forged from a dedicated forging and feature shot peening, oil slots, and coated bronze

thrust washers.

• Bottom end gasket kits are made from premium materials, exceeding OEM standards, to provide exceptional seal between

critical mating surfaces.

• Main bearings are manufactured to the highest quality standards. Each is case hardened for maximum life and smooth opera-

tion at high RPM’s.

• Corrosion resistant surface treatment to prevent corrosion and pitting over long term use or storage. This will add to the life

as well the strength of the assembly.

• Top end of rod is bushed for oil retention and eliminates pin galling. The bottom end rod bores are case hardened to 58-62

RC to optimize bearing running surface.

• The crank pin bearings are manufactured from the highest quality, hot rolled steel case hardened to 58-62 RC to extend the

lifetime of the assembly.

• Caged needle roller bearings to provide the highest possible RPM.

BOTTOM END REBUILD KITS